Primary Crusher Iron

Primary Crusher Optimisation for Improved

2024年8月29日 The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore The crushing plant can be In some industries, for example, iron ore or coal, where a specific product size is required (iron ore –30 + 6 mm), a careful choice of jaw settings and screen sizes is required to Primary Crusher an overview ScienceDirect Topics2014年11月15日 The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher Fuzzy TOPSIS method to primary crusher selection for Golegohar Iron 2022年1月1日 The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of Comminution and classification technologies of iron ore

.jpg)

Primary Crushing Station SpringerLink

2023年1月31日 Primary crushing station is a facility for primary crushing of ore (rock) According to the mining technology, the primary crushing station can be divided into 2020年6月1日 The part of aggregate processing investigated in this paper is the crushing, specifically primary crushing using a jaw crusher Coarse aggregates for unbound use Influence of jaw crusher parameters on the quality of primary Primary crushing brings runofmine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry” Primary Crushing SpringerLink2024年6月28日 An ideal primary crusher can not only handle the toughest materials with ease, but also ensure a stable high output In this article, FTM Machinery introduces What Crusher Should You Choose for Primary Crushing?

.jpg)

Mining crushers SuperiorTM MKIII Primary Gyratory

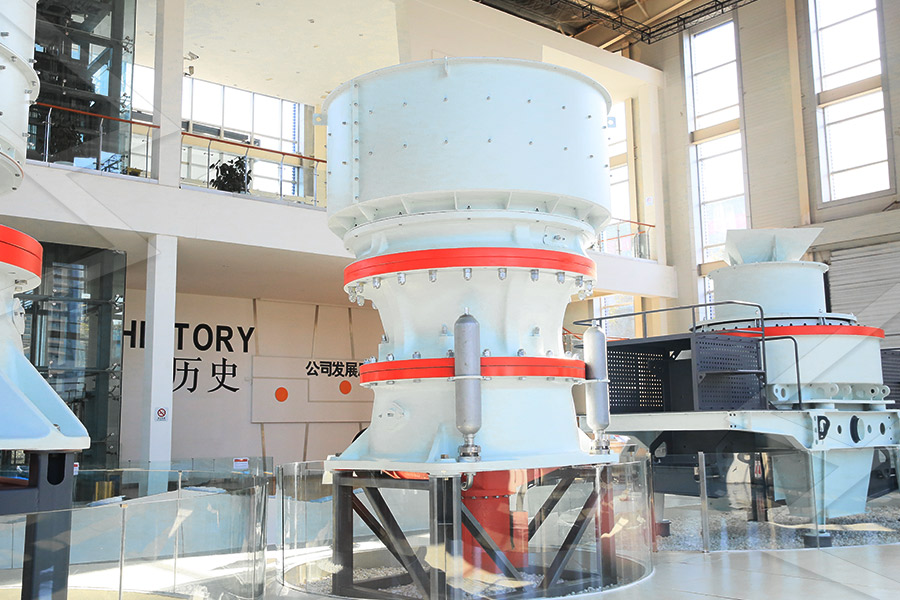

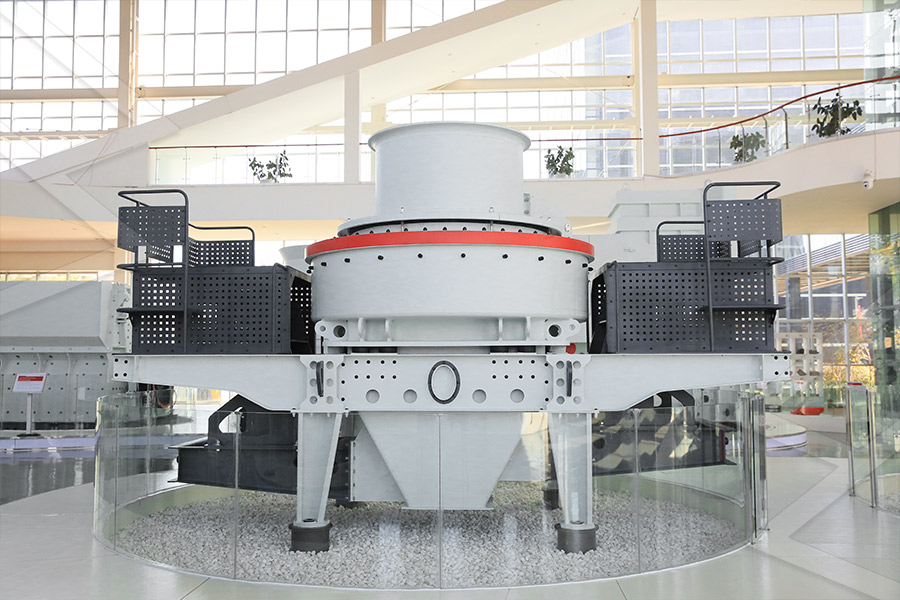

2022年12月28日 Outotec’s line of Superior™ Primary Gyratory crushers are designed to meet the demand for high efficiency and high capacity mining installations 2014年11月15日 The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in IranFuzzy TOPSIS method to primary crusher selection for Golegohar Iron 2023年2月28日 The primary crusher receives the materials directly from the mine or quarry, and its size reduction ratio ranges from 3:1 to 7:1 The primary crusher can be a jaw crusher, gyratory crusher, or impact Primary and Secondary Crushing: Understanding Superior™ MKIII crushers bring higher capacity making this crusher the most capex efficient primary gyratory crusher in the industry Reduced downtime Superior™ MKIII primary gyratory crushers have new sets of Superior™ MKIII Series primary gyratory crushers

.jpg)

Types of Crushers: What You Need to Know HUATAO GROUP

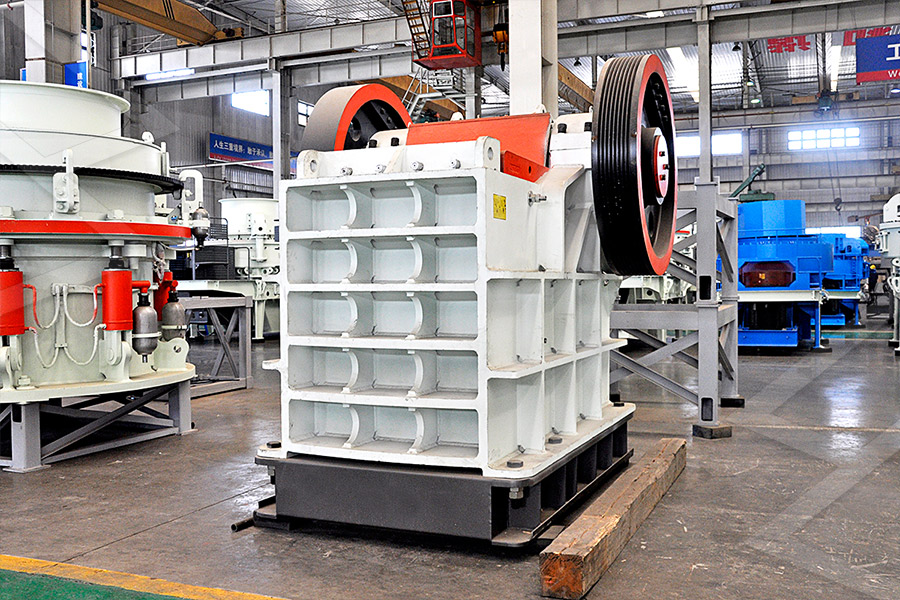

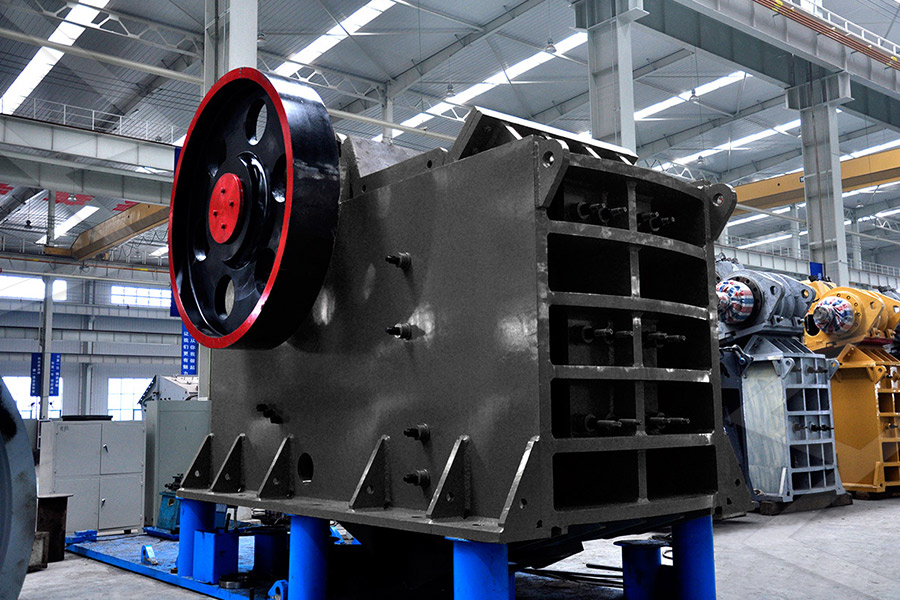

2023年8月2日 Jaw crushers are largescale, heavyduty machinery typically constructed with cast iron and/or steel Often considered a basic machine, jaw crushers have their place in the industry They are often used to reduce rock into nonuniformed gravel To find out more about primary jaw crusher check out our blog Cross section of a Kleeman primary 2023年2月28日 What is the capacity of a typical primary jaw crusher? The capacity of a primary jaw crusher depends on the machine’s size and the material being crushed Typical capacities range from a few hundred tons per hour to more than 10,000 tons per hour Types of Primary Jaw CrushersPrimary Jaw Crusher – Everything You Need to Know2024年2月20日 BHP WA Iron Ore Asset President Tim Day said this was a significant milestone and project, with an expected total investment of US$943 million (100% basis) including construction of a new 30 Mtpa primary crusher and a 12kilometre overland conveyor to transport the ore from the Mount Helen and Silver Knight iron ore deposits to Western Ridge Crusher Project progresses to execution BHP4 天之前 A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries Its processing capacity is as high as 14,082 t/h, and the feed particle size can reach 1,350 mm If unbreakable materials such as iron pieces enter the crushing chamber, the hydraulic cylinder will lower the moving Large Capacity Gyratory Crushers for Primary Crushing Fote

.jpg)

Crusher Nakayama Iron Works

NEW Jaw Crusher untuk Primary Crushing RC3624 / RC4224 / RC4228 / RC4832 / RC5042 / RC6048 Gambaran Umum Tipe RC adalah jaw crusher jenis baru yang siap merespon era baru dengan struktur yang sederhana, mampu menghancurkan gumpalan besar, ekonomis, tingkat produktivitas yang tinggi, dan kemudahan dalam perawatan 2022年8月18日 Innovation has an important role in improving the productivity, safety and sustainability of mining operations Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies The innovative A MinetoCrusher Model to Minimize Costs at a Truckless OpenPit Iron 2023年2月28日 Choosing the right type of primary crusher for your operation depends on several factors, including the maximum size of the material to be crushed, the desired output size, and the capacity of the The Complete Guide to Primary Crushing, 2021年3月25日 The right primary crusher for an application depends on several factors: Material to be crushed Feed size Desired product size Capacity required Compressive strength of the feed Moisture content What Type of Crusher Is Best for Primary

.jpg)

® NP Series™ Horizontal shaft impact (HSI)

2023年7月20日 crusher primary range has been designed to increase the crushing process productivity thanks to its high reduction ratio Usually utilized in the first crushing stage of the size reduction process in aggregates production, recycling and mining operations The Primary range consists of tailored primary crusher ® NP1620™ andSelection of suitable primary crusher from all of available primary crushers is a multicriterion decision making (MCDM) problem The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in IranFuzzy TOPSIS method to primary crusher selection for Golegohar Iron 2016年2月24日 • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variationsCrushing Plant Design and Layout Considerations 911 Nakayama Iron Works website Primary Crusher AC2415 / AC3219B / AC4820 Overview Based on the design that focused on both asphalt and concrete crushing, AC crusher is the only available primary crusher in the marketCrusher Nakayama Iron Works

.jpg)

Fuzzy TOPSIS method to primary crusher selection for

2017年8月29日 Selection of suitable primary crusher from all of available primary crushers is a multicriterion decision making (MCDM) problem The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in Iran2024年2月18日 Whether processing soft limestone or the more resistant iron ore, the wear on these manganese steel plates is gradual and uniform, ensuring a consistent feed and output size The machinery’s highimpact movement typically relates to a high production rate in a primary crusher For instance, a standard jaw crusher diagram might show a Jaw Crusher Diagram: Simplified Guide JXSC2022年12月28日 Superior™ Primary Gyratory MKIII Range Perfect mix of experience and innovation 100+ years of proven experience, latest advancements in metallurgy and thousands of crusher installations around the world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliabilityMining crushers SuperiorTM MKIII Primary Gyratory%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources

.jpg)

Gyratory and Cone Crusher ScienceDirect

2016年1月1日 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h The largest size of the runofmine ore was 1000 mm The required product size was less than 162 mm Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°2020年7月10日 Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job Depending on the setup, primary crushing will take the larger What Is Primary, Secondary, and Tertiary From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, equipment is manufactured to meet your material reduction requirements The crushers are built to perform Crushing 2009年1月1日 Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of low energy consumption, low operating costs, and improving the energy Processing of Magnetite Iron Ores–Comparing Grinding Options

Primary Gyratory Crusher High Performance GY Series

2022年7月6日 PRIMARY GYRATORY CRUSHER High Performance GY Series A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary 2024年2月6日 High capacity suitable for robust primary crushing of large ores: Dodge: Softer and smaller, coal, gypsum, soft shale: Effective for softer materials with a gentle crushing action: Stationary: All types, iron ore, granite, and highvolume quartz: Ideal for largescale operations requiring continuous, highcapacity crushing: Track MountedUnderstanding Types of Jaw Crusher: A Comprehensive 2022年11月21日 thyssenkrupp gyratory crushers in primary crushing is second to none KB 6389 for iron ore Capacity: 6,200 t/h KB 6375 for aggregates Capacity: 2,600 t/h KB 5475 for iron ore Applications • Large ore mines • Limestone and cement industries • Open pit and underground mining • Aggregates industry Features • Cyclopalloid spiral Industrial Solutions Gyratory crushers ThyssenKrupp2024年8月9日 C120 Primary Jaw Crusher for Rock Stone Iron Ore Crushing Features Advantages: 1 Modular, weldfree frame structure 2 Durable jaw assembly 3Integral cast steel bearing housing 4 Repairable crusher rack C120 Primary Jaw Crusher for Rock Stone Iron Ore Crushing Specification: Model: C120: Motor : 160KW(200HP)C120 Primary Jaw Crusher for Rock Stone Iron Ore Crushing

Primary vs Secondary Crushers: Understanding the

2023年2月28日 Primary crushers are used in a variety of industries, including mining, construction, and demolition They are used to crush a variety of materials, including coal, limestone, and iron ore Factors to Consider When Selecting a Primary Crusher When selecting a primary crusher, there are several factors to consider, including: Primary Impact Crushers are designed as primary reduction units for materials of medium to low silica contents such as limestone, gypsum 180 years of experience Made in Germany allows for quick PRIMARY IMPACT CRUSHER HPI Having a primary jaw crusher like the Omega J1065T that feeds directly into an impact crusher such as th Rockster R1000S will make it easier to increase the efficiency of your crushing output Large tracked jaw What is a Primary Crusher? Machinery Partner2022年1月1日 To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or Comminution and classification technologies of iron ore

.jpg)

Jaw Crusher Eriez

Jaw Crusher The range of MACSALAB Jaw Crushers is ideal for primary crushing of samples of moderately hard materials, including coal, limestone, ore, minerals and bricks and rubble Units are sturdily constructed in Cast Iron and utilise reversible hardwearing Manganese Steel jaws Features Standard motors with starters + overload protection2016年2月17日 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing Gyratory Crushers 911 Metallurgist2024年2月23日 Picking out the right equipment for primary crushing is a big deal because it really affects how well the whole crushing and processing setup works For top primary crusher manufacturers, read 10 Best Crusher Manufacturers for Your Mining Project There are a few important things to think about to make sure you’re making the best choicePrimary Crushing: A Comprehensive Guide JXSC2024年8月29日 of crusher is usually used with soft and nonabrasive material such as coal, limestone, gypsum or soft metallic ores A typical iron ore fines crusher flow sheet is shown in Figure 1, using a highcapacity sizer as a primary crusher followed by screening and cone crushers HiStorY Batch crushing plantsMobile crushing and Screening Plant Applications for

Construction, Working and Maintenance of Practical

2018年12月26日 Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in Cast Iron Stone Crusher Machine, 200 TPH Ask Price Maruti Fabritech Engineers Contact Supplier VINDJYA Mild Steel Stone Crusher 30X24 For Industrial, Capacity: 75 Tph Stone crusher 2010ah series primary jaw crusher; Rew mild steel single toggle jaw crusher, for construction iStone Crusher at Best Price in India India Business Directory2014年11月15日 The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in IranFuzzy TOPSIS method to primary crusher selection for Golegohar Iron 2023年2月28日 The primary crusher receives the materials directly from the mine or quarry, and its size reduction ratio ranges from 3:1 to 7:1 The primary crusher can be a jaw crusher, gyratory crusher, or impact Primary and Secondary Crushing: Understanding

.jpg)

Superior™ MKIII Series primary gyratory crushers

Superior™ MKIII crushers bring higher capacity making this crusher the most capex efficient primary gyratory crusher in the industry Reduced downtime Superior™ MKIII primary gyratory crushers have new sets of 2023年8月2日 Jaw crushers are largescale, heavyduty machinery typically constructed with cast iron and/or steel Often considered a basic machine, jaw crushers have their place in the industry They are often used to reduce rock into nonuniformed gravel To find out more about primary jaw crusher check out our blog Cross section of a Kleeman primary Types of Crushers: What You Need to Know HUATAO GROUP2023年2月28日 What is the capacity of a typical primary jaw crusher? The capacity of a primary jaw crusher depends on the machine’s size and the material being crushed Typical capacities range from a few hundred tons per hour to more than 10,000 tons per hour Types of Primary Jaw CrushersPrimary Jaw Crusher – Everything You Need to Know2024年2月20日 BHP WA Iron Ore Asset President Tim Day said this was a significant milestone and project, with an expected total investment of US$943 million (100% basis) including construction of a new 30 Mtpa primary crusher and a 12kilometre overland conveyor to transport the ore from the Mount Helen and Silver Knight iron ore deposits to Western Ridge Crusher Project progresses to execution BHP

Large Capacity Gyratory Crushers for Primary Crushing Fote

4 天之前 A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries Its processing capacity is as high as 14,082 t/h, and the feed particle size can reach 1,350 mm If unbreakable materials such as iron pieces enter the crushing chamber, the hydraulic cylinder will lower the moving NEW Jaw Crusher untuk Primary Crushing RC3624 / RC4224 / RC4228 / RC4832 / RC5042 / RC6048 Gambaran Umum Tipe RC adalah jaw crusher jenis baru yang siap merespon era baru dengan struktur yang sederhana, mampu menghancurkan gumpalan besar, ekonomis, tingkat produktivitas yang tinggi, dan kemudahan dalam perawatan Crusher Nakayama Iron Works2022年8月18日 Innovation has an important role in improving the productivity, safety and sustainability of mining operations Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies The innovative A MinetoCrusher Model to Minimize Costs at a Truckless OpenPit Iron