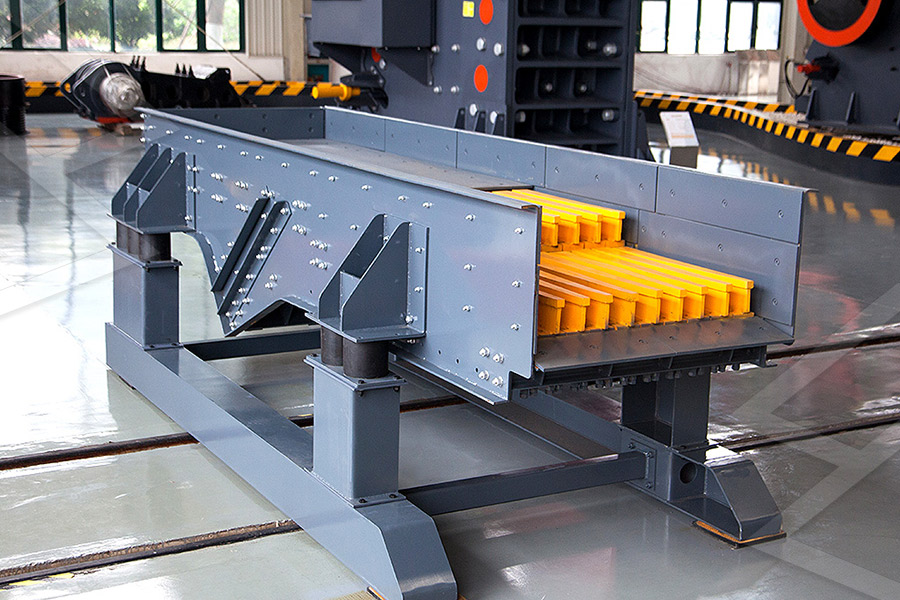

Durable In Use And Good Design Waste LeadZinc Vibrating Screen

Collaborative optimization of linear vibrating screen

2023年7月1日 In this paper, the amplitude fluctuation value in the steadystate phase is used as the evaluation index reflecting the stability of the dynamic response of the 2019年4月1日 Large vibrating screen is the key equipment to improve the clean and efficient utilization of coal In recent years, various advanced design techniques and A review on the advanced design techniques and methods of vibrating 2020年3月4日 In this paper, the modal analysis and dynamic simulation of a large linear vibrating screen are carried out by using Abaqus, a large general finite element software, Structural Analysis and Optimization Design of Linear 2019年4月1日 Large vibrating screen is the key equipment to improve the clean and efficient utilization of coal In recent years, various advanced design techniques and A review on the advanced design techniques and methods of vibrating

Structural Analysis and Optimization Design of Linear Vibrating Screen

2020年3月5日 In this paper, the modal analysis and dynamic simulation of a large linear vibrating screen are carried out by using Abaqus, a large general finite element software, 2022年5月1日 Because powder materials usually contain a certain amount of moisture, highfrequency vibration can effectively separate materials with different particle sizes, Design of Vibrating Screen Separation Equipment for 2023年10月19日 To strengthen the screening efficiency of traditional vibrating screens, a new type of vibrating screen, namely the composite vibrating screen, has been proposed based on the Lissajous vibration Research on the screening mechanisms of 2024年8月21日 The analysis results show that the vibrating operates stably without transverse swing, the stress distribution of the screen body is uniform, can bear large Dynamic characteristics analysis of a circular vibrating

Essential Guide to Vibrating Screen Design: Benefits, Types

2024年7月26日 The future of vibrating screen design is aimed at increasing productivity, decreasing the need for maintenance, and increasing the lifespan of the equipment Our Durable in use and good design vibrating screen for waste water delivers high performance with a contemporary design We have the Vibrating Screen solutions for all Dayong Durable in use and good design vibrating screen for waste A vibrating screen is formed by a vibrant chassis that supports one or several screening surfaces it will already have traveled half way of the surface In other words, we waste surface with a very important loss of Basic concepts of vibrating screens: What they 2022年2月15日 What type of screen media is best for my Vibratory Screen? Screen media is all about open area, or the number of openings in the screen The more openings in the screen, the more opportunities the How To Size and Select a Vibrating Screen for

.jpg)

Vibrating Screen Maintenance 101 Waste

2023年7月30日 Daily: Take a daily look at cleanliness, proper greasing, loose parts, and any changes in oscillating behavior Keep the vibrating screen clean of sticky or cakedon material to prevent interference with 2023年4月16日 In Figure 1b, the amorphous glassy component of HGPW is seen in the XRD patternPhase detection in XRD diffractograms was corroborated by reference codes for quartz (010862339) and mullite (010791276) Sulphuric acid (98%) from Chemlab, sodium hydroxide (Sigma Aldrich), sodium sulphide (Sigma Aldrich), and oxalic acid A novel method has been developed to efficiently recover valuable lead A horizontal screen is a nonconventional design that has unique properties that differentiate it from other types of conventional screen Its most obvious advantage is its working angle While conventional screens work at an angle of between 15° and 30°, horizontal screens work in parallel to the ground, or at a slight incline of between 0 Vibrating Screen Types MEKAA Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification, sizing, scalping and recycling Designed for your specific operation, our Dry Vibrating Screens come in a wide range of sizes ranging from 09m to 48m wide and up to 110m longDry Vibrating Screens for mining and industrial FLSmidth

Structural Analysis and Optimization Design of Linear Vibrating Screen

2020年3月5日 Due to linear vibrating screen’s high efficiency, simple structure, multilevel advantages, it has been widely used in mines, coal, smelting, light industry, chemical industry, medicine, food, and other industries []The forced vibration of the vibrating screen under a large load, longterm uninterrupted work is easytooccur fatigue damage, and 2 天之前 Leadzinc ore usually exists in the form of sulfide ores, such as sphalerite and galena Flotation is the most commonly used method The leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravityflotation, magneticflotation, and gravitymagneticflotation, in Lead Zinc Processing Solution JXSC Machinery2009年9月1日 Conventional static strength calculation and analogy method was used in the design of vibrating screen in our country at present which neglect the dynamic characteristic influence of higher modal frequencies on the vibrating screen [4] High exciting force is likely to lead to fatigue damage of vibrating screenDynamic design theory and application of large vibrating screen2022年9月1日 Unlike the traditional vibrating screens, the VFFS is a twobody vibration system, including two vibrating bodies, comprising the main screen frame and a floating screen frame In this paper, a singledeck type of 0827 VFFS excited by an exciter was designed and produced, and a fivedegreeoffreedom translational and rotational Comparison of flipflow screen and circular vibrating screen

.jpg)

Vibrating Screen Mine Screening Equipment

2024年8月17日 Vibrating Screen Machine Working Principle Vibrating screen uses electric exciter as a vibrating source, the material will be thrown around the screen, at the same time doing forward sports, in order to 6 天之前 "SYC series ultrasonic vibratory screen " is equipped with the smart ultrasonic control transducer which can convert 220V,50HZ single phase or 110V 60HZ single phase to the 3036KHZ high frequency Screening Accuracy Metal Powder Sieving 2021年7月27日 Vibrating screen is a kind of vibrating screening mechanical equipment suitable for any particle, powder and mucus At present, it is commonly used in China’s food, medicine, chemical Types Of Vibrating Screen and How It Works2022年9月1日 Unlike the traditional vibrating screens, the VFFS is a twobody vibration system, including two vibrating bodies, comprising the main screen frame and a floating screen frame In this paper, a singledeck type of 0827 VFFS excited by an exciter was designed and produced, and a fivedegreeoffreedom translational and rotational Comparison of flipflow screen and circular vibrating screen

Lead Zinc Processing Solution JXSC Machinery

2 天之前 Leadzinc ore usually exists in the form of sulfide ores, such as sphalerite and galena Flotation is the most commonly used method The leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravityflotation, magneticflotation, and gravitymagneticflotation, in The Spaleck recycling waste screen is carried out as a vibrating screen with a circular motion and is driven by a highperformance and equally energy efficient threephase AC motor The blind bottom on the infeed side guarantees an efficient utilization of the screening surface, a good material flow, increases the service life of the screening Recycling Waste Screen SPALECK since 1869The linear vibrating screen can cause the material to be thrown up and move linearly on the screen surface, so as to achieve the purpose of screening the material There is a grounding device in the motor, and the lead end has a mark It can also be grounded by a solid bolt The motor lead adopts fourcore rubber cable YZ500V When Linear vibrating screen Haiside2021年3月12日 This type of screen is also used to process waste like food effluent, wastewater processing, and much more This is a very powerful vibrating screen type that comes with a long screening life It has a durable and sturdy design which makes it serviceable for long periods The gyratory vibrating screen is mainly used in filtering, Need to know about different vibrating screen types and

Tabor Reverse Incline Vibrating Screen Durable Elgin

2022年8月7日 Durable Tabor Reverse Incline Vibrating Screen 1 Rubber lined or ceramic water box 2 Linearmotion TH Drive 3 Huckbolted assembly on all major body components 4 Highquality wearresistant side linings (not shown) 5 UHMWlined effluent pan (optional) 6 Steel coils for floor mounting 7 A variety of paint options for maximum corrosion 2015年9月8日 Demand for large vibrating screen is huge in the mineral processing industry As bending and random vibration are not considered in a traditional design method for beam structures of a large vibrating screen, fatigue damage occurs frequently to affect the screening performance This work aims to conduct a systematic mechanics analysis Improvement for design of beam structures in large vibrating screen 2022年5月1日 Screen Type Selection: Screen Grid, suitable for coarse screen, the size of more than 50 mm screen The 12th Asia Conference on Mechanical and Aerospace Engineering (ACMAE 2021) Journal of Physics Design of Vibrating Screen Separation Equipment for 3 天之前 Round vibrating screeners use a circular vibratory motion and are suited to both liquid and powder applications While both linear and circular sieves use vibration to process materials, circular screening machines Vibrating Sieve, Vibratory Sieves, Screens,

.jpg)

Trash Screen for separating debris from raw feed FLSmidth

Multiple Vibrating Screen goovi® the Trash Screen offers improved throughput and productivity, while being durable enough to significantly cut down on maintenance and repair costs What we offer For your safety its recommended to not use Internet Explorer Browser To get best of browsing features in flsmidth, please choose Google The modular design of the vibrating screen machines allows for a wide range of customized configurations that can be flexibly adapted to the respective product Due to years of experience and the universal adjustability of the screens, very high separation sharpness can be achievedVibration screening machine classifying sorting Allgaier2019年4月1日 A large vibrating screen is crucial to advancing the large scale coal preparation for the clean and efficient utilization of coal A comprehensive review of advanced design techniques and methods for a vibrating screen have been presented Almost 71% of all the literature were published during last five years (2)A review on the advanced design techniques and methods of vibrating The Spaleck recycling waste screen is carried out as a vibrating screen with a circular motion and is driven by a highperformance and equally energy efficient threephase AC motor The blind bottom on the infeed side guarantees an efficient utilization of the screening surface, a good material flow, increases the service life of the screening Recycling Waste Screening Machine SPALECK USA

Material recovery and recycling of waste tyresA review

2022年9月1日 Thus, this reactor design has reached a relatively high degree of development and has been commonly applied to the pyrolysis of biomass and different solid wastes Pyrolyzed waste tyres of particle size between 2 and 4 mm in a continuous auger reactor was conducted by Martínez et al (Martínez et al, 2013a, Martínez et al, 2013b) 2023年12月2日 The capacity loss due to chemical corrosion was further assessed by fully stripping the Zn electrode after 24 h of resting in different alkanediol containing and additivefree electrolytes 1% Butanediol and 1% Pentanediol demonstrate the best zinc retention of 983% and 987%, respectively (Figure S35, Supporting Information) after resting Highly Potent and Low‐Volume Concentration Additives for Durable Many printing processes use heat to drive off these solvents This processes dries or “sets” the ink This can lead to health and air quality problems if the solvent emitted are not properly taken care of or treated Hormone Disruption PVC is a hard, ridged material Think of PVC sprinkler pipesEnvironmental Review Of Screen Printing Methods Fairware2015年9月8日 Demand for large vibrating screen is huge in the mineral processing industry As bending and random vibration are not considered in a traditional design method for beam structures of a large vibrating screen, fatigue damage occurs frequently to affect the screening performance This work aims to conduct a systematic mechanics analysis Improvement for design of beam structures in large vibrating screen

Benefits of Vibrating Screens Aggregates

2020年10月7日 What Is A Vibrating Screen? As the name implies, vibrating screen design is based on the principle of transferring vibrations to a screening surface in order to separate and classify various particles by We do more than make the world's best water well screens; we provide you with the necessary design analysis and technical support to deliver efficient and productive water well in coal, iron ore, gold, copper, phosphate, lead, zinc, bauxite, sand, gravel and many more Established in year 1993, Johnson Screens (india) Pvt Ltd is Johnson Screens (india) Pvt Ltd in Kalol, Gandhinagar, Our Durable in use and good design vibrating screen for waste water delivers high performance with a contemporary design We have the Vibrating Screen solutions for all your needs Email: lisa@dyvibratingscreen Whatsapp: 8261Dayong Durable in use and good design vibrating screen for waste 2022年12月1日 While there are several options for material handling systems in the waste management, recycling, and aggregate industries, vibrating screens have several advantages that make them the preferred method end of the deck Decking can be made of wire mesh, steel, rod decks, or polyurethane panels, among other things Each design Vibrating Screens Types, Benefits and More DPH Engineering

Vibrating Screen|Vibrating Screen Series|Fong Chuan

Oil cooling circulating system The oil cooling circulating system is a new feature of the FongChuan Vibrating Screen Series Driven by the hydraulic pressure, cooling water is transported from an external system to the main drive continuously, in order to adjust the high temperature of lubricant generated by bearing friction and maintain the best They are also used to dewater or dry waste material before disposal This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed High capacity screening equipment can screen or classify material ranging in sizes from 1/8 inch (3mm) down to 325 meshVibratory Screening Dewatering Equipment (1/2 in to 325 In the case of a vibrating screen, the material to be separated is fed to the top screen and simultaneously the screens are vibrated either electrically or mechanically at a frequency of 1000 to 3500 per minute High opening rate create high screening efficiency and production capacity, but lead to short life of screen panels (2) Screen Vibrating Screen Efficiency Calculations and Improvement大量翻译例句关于"durable in use" – 英中词典以及8百万条中文译文例句。 振动筛采用筒体式偏心轴激振器及偏块调节振幅,物料筛淌线长,筛分规格多,具有结构可靠、激振力强、筛分效 率高、振动噪音小 、 坚固 耐用 、维 修方 便、 使用安 全等 特点,该振动筛广 泛 应用 于矿 山、 建材 durable in use 英中 – Linguee词典

Dynamic design theory and application of large vibrating screen

2009年9月1日 Conventional static strength calculation and analogy method was used in the design of vibrating screen in our country at present which neglect the dynamic characteristic influence of higher modal frequencies on the vibrating screen [4] High exciting force is likely to lead to fatigue damage of vibrating screenIn this study, the preparation and electrochemical application of a chromium(III) oxide modified carbon paste electrode (CrCPE) and a screen printed electrode (SPE), made from the same material and optimized for the simple, cheap and sensitive simultaneous determination of zinc, cadmium, lead, copper and the detection of silver ions, is Sensors Free FullText Determination of Zinc, Cadmium, Lead 2023年11月27日 A vibrating screen, also known as a separator or sifter, is a machine that is used to separate particles or materials into different sizes based on their particle size or shapeHere is a guide covering the Vibrating Screen Guide: Definition, Types, The aggregate vibrating screen works by vibrating the screen mesh, which allows the smaller particles to fall through the openings while the larger particles remain on the screen The screen mesh can be made of various materials such as stainless steel, highstrength carbon steel, or polyurethaneHow To Size and Select a Vibrating Screen for an Aggregate

Vibrating Screens for powder and bulk solids

2023年7月30日 Figure 1 : Round vibratory sifter design What is the working principle of a vibrating screen ? Vibrating sifters are equipped with a sieving deck, made of a wire mesh or a perforated plate on which the bulk solids to check is loaded2023年7月1日 1 Introduction The vibrating screen is used for particle size sorting of granular materials, and its application is extremely wide In addition to the mining and steel industries, it has also been gradually applied to the fields of food, machinery, water conservancy, construction and pollution treatment in recent years (Liu, 2009)The Collaborative optimization of linear vibrating screen A Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification, sizing, scalping and recycling Designed for your specific operation, our Dry Vibrating Screens come in a wide range of sizes ranging from 09m to 48m wide and up to 110m longDry Vibrating Screens for mining and industrial FLSmidth2023年7月30日 Daily: Take a daily look at cleanliness, proper greasing, loose parts, and any changes in oscillating behavior Keep the vibrating screen clean of sticky or cakedon material to prevent interference with equipment operation Weekly: Operations should inspect structural components and screen media installation weekly Monthly: Look at the Vibrating Screen Maintenance 101 Waste Advantage

.jpg)

Vibrating Feeders: How They Work and Effectiveness

2023年5月18日 The good news: General Kinematics creates one machine that provides the happy medium to all of these objectives The PARAMOUNT II® Vibrating Feeder does more work but requires less energy Why? PARAMOUNT II® Vibrating Feeders offer a revolutionary design called a TwoMass vibratory systemA vibrating screen is formed by a vibrant chassis that supports one or several screening surfaces it will already have traveled half way of the surface In other words, we waste surface with a very important loss of production and also the area where the pile is made will receive severe wear with the consequent extra maintenance expenses Basic concepts of vibrating screens: What they are, what they 2019年4月1日 A large vibrating screen is crucial to advancing the large scale coal preparation for the clean and efficient utilization of coal A comprehensive review of advanced design techniques and methods for a vibrating screen have been presented Almost 71% of all the literature were published during last five years (2)A review on the advanced design techniques and methods of vibrating 2022年2月15日 What type of screen media is best for my Vibratory Screen? Screen media is all about open area, or the number of openings in the screen The more openings in the screen, the more opportunities the particles will have to pass through and the more efficient the screen will be However, more openings in the screen can decrease the wear life of How To Size and Select a Vibrating Screen for an